Material Platform Technology

Hybrid Material Compositions

Hybrid Liners

Benefits and Uses

A reduction of as little as 1% in friction inside the engine block through implementation of improved lubrication technologies could result in 1 billion liters of fuel saved annually worldwide.

Intelligent Composites, LLC, (Milwaukee, WI) is manufacturing a novel material platform technology in the form of a self-lubricating metal-matrix composite (MMC).

They offer the potential to reduce weight and oil consumption within internal combustion engines while improving energy efficiency.

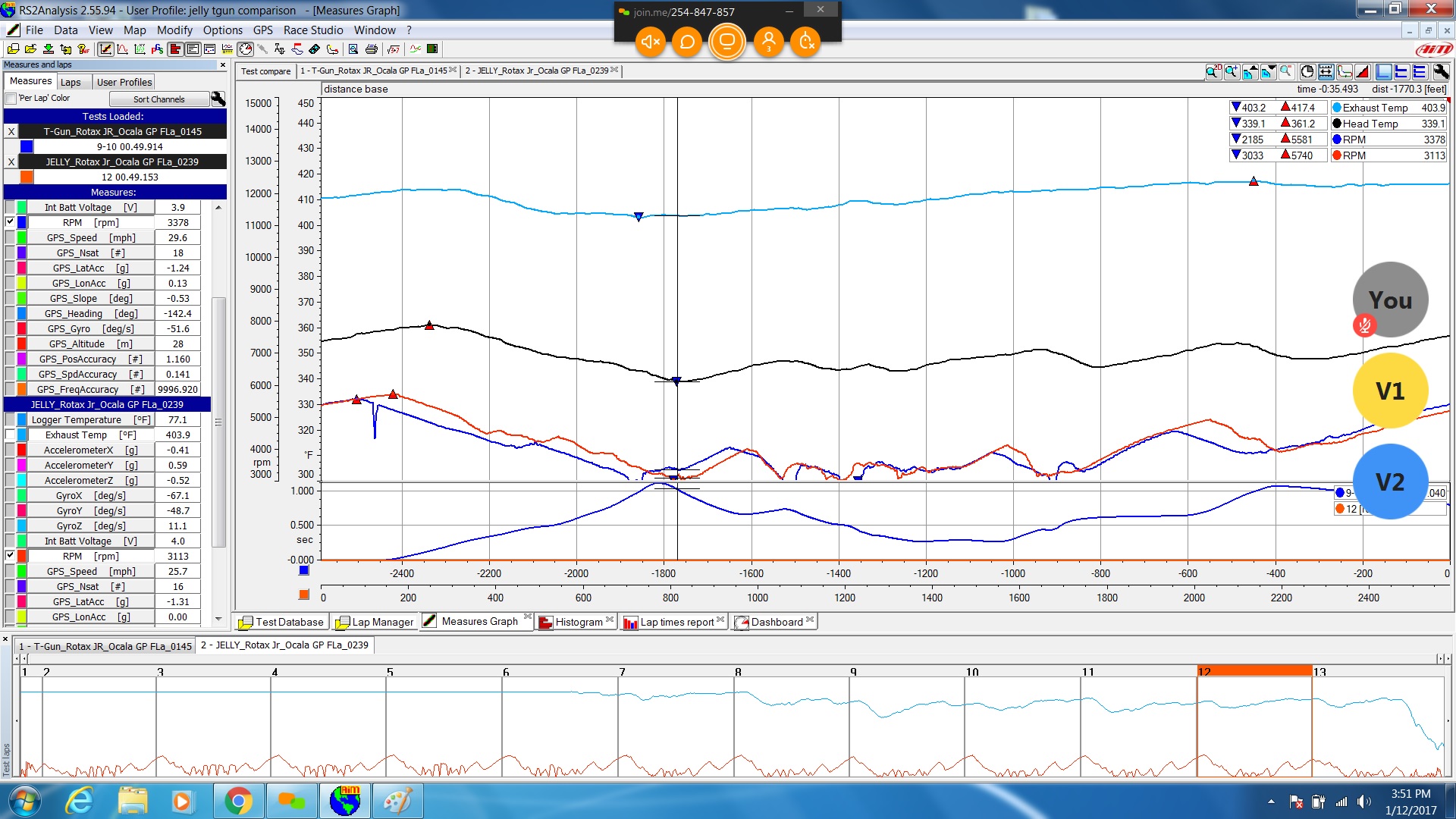

The engine with the Intelligent Composites liner was consistently 40-50 degrees cooler

than the stock cast iron lined engine.

200 million small engines are sold annually worldwide

There are over 1.2 billion vehicles on the road today

Get up to 10% increase in horsepower.

Over 100 years of casting experience

IMPACT

Friction accounts for up to 20% of the parasitic losses in IC engines, 40-50% of which can be tied directly to the piston system including the cylinder liner and ring wear. Strategies to reduce friction of the cylinder liner can drastically improve fuel efficiency, and reduce emissions, vibration, noise, heat and cost over the lifetime of the engine.

Almost one sixth of the energy provided by automotive fuel goes to overcoming frictional losses.